Lab 001 - Matthew Venn

Matthew Venn is a technology communicator and electronic engineer. His lab was equipped to design, prototype and test electronics and electromechanical projects. Most recently he has been involved in the open source silicon movement, focussing on his Zero to ASIC course . This has put more emphasis on being able to film and edit videos.

Feel free to connect with him on LinkedIn or Twitter !

Welcome to the first iteration of lab inspiration! Do you have a lab that you’d like to share with the community? Simply send an email and introduce yourself!

Thank you!

Guillaume (

@embedsys

)

Inside Matthew’s lab

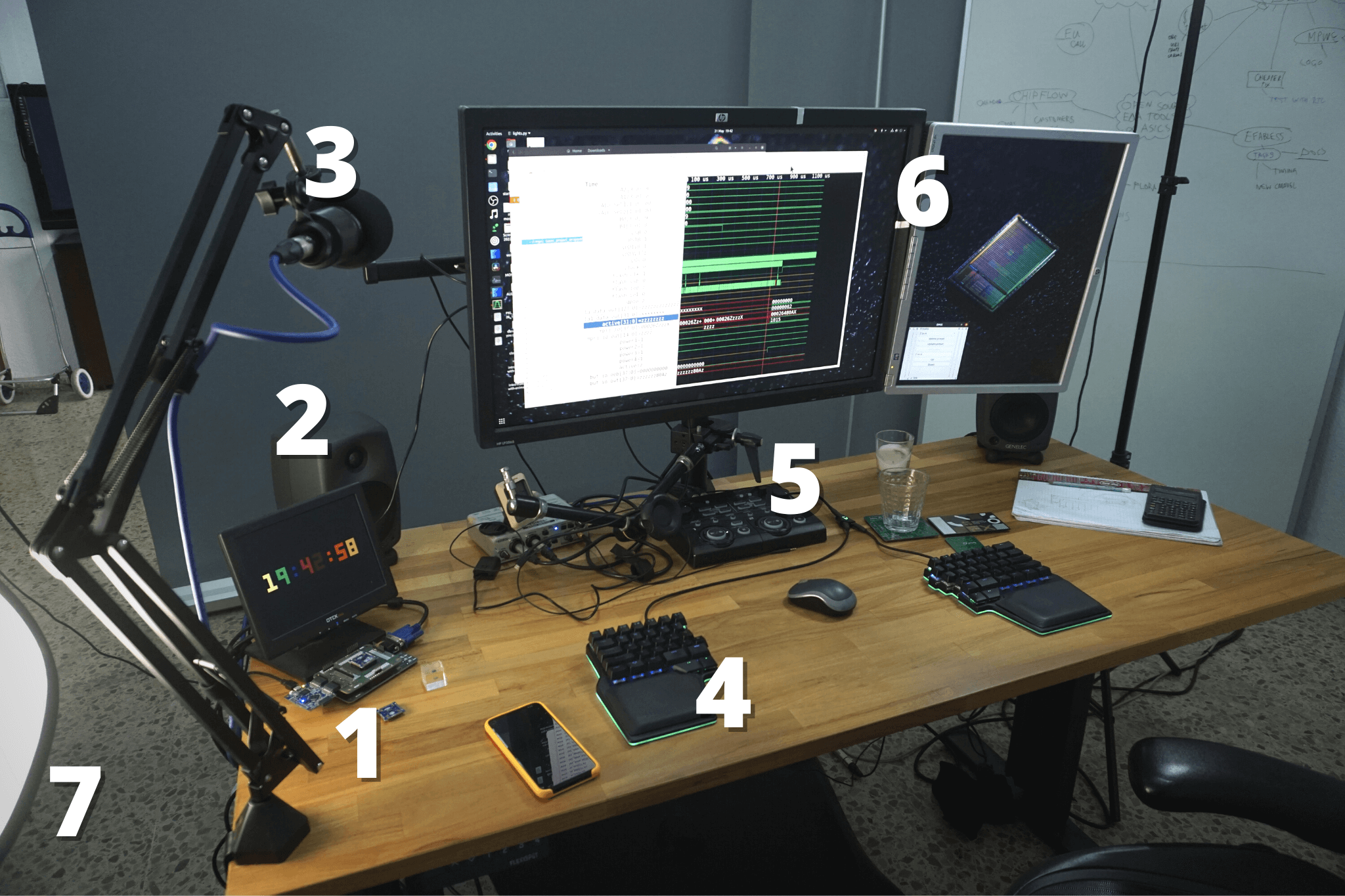

- My first ASIC contained 8 separate designs , one of which was a clock that can drive a VGA panel. Very happy to have this working on my desk!

- I love music, so I enjoy having some fancy speakers close by.

- I make videos for my courses and content marketing, so having a big mic is nice for audio quality. This goes into an external USB sound card, which also lets me monitor my voice in headphones - that’s a good tip if you find yourself getting a sore throat from talking on calls.

- Before I started making chips, I was CTO for Dygma (launching a new keyboard soon!) and this is the keyboard we made. I wouldn’t go back to a non-split keyboard now.

- My mic goes through this looper, mostly for having fun and taking musical breaks during the day. I’m still a bit scared to use it on my biz calls!

- My PC is mounted under the desk, I got a reconditioned HP TE01. I need a graphics card for Davinci Resolv, my video editor of choice. I’ve found 2 monitors to be handy for recording screen content or running webinars, as I can keep the controls on one screen and the video on the main one.

- I use a Sony A6000 camera for videos and calls. It does help to have lights, and I use Neewar LED lights and diffusers.

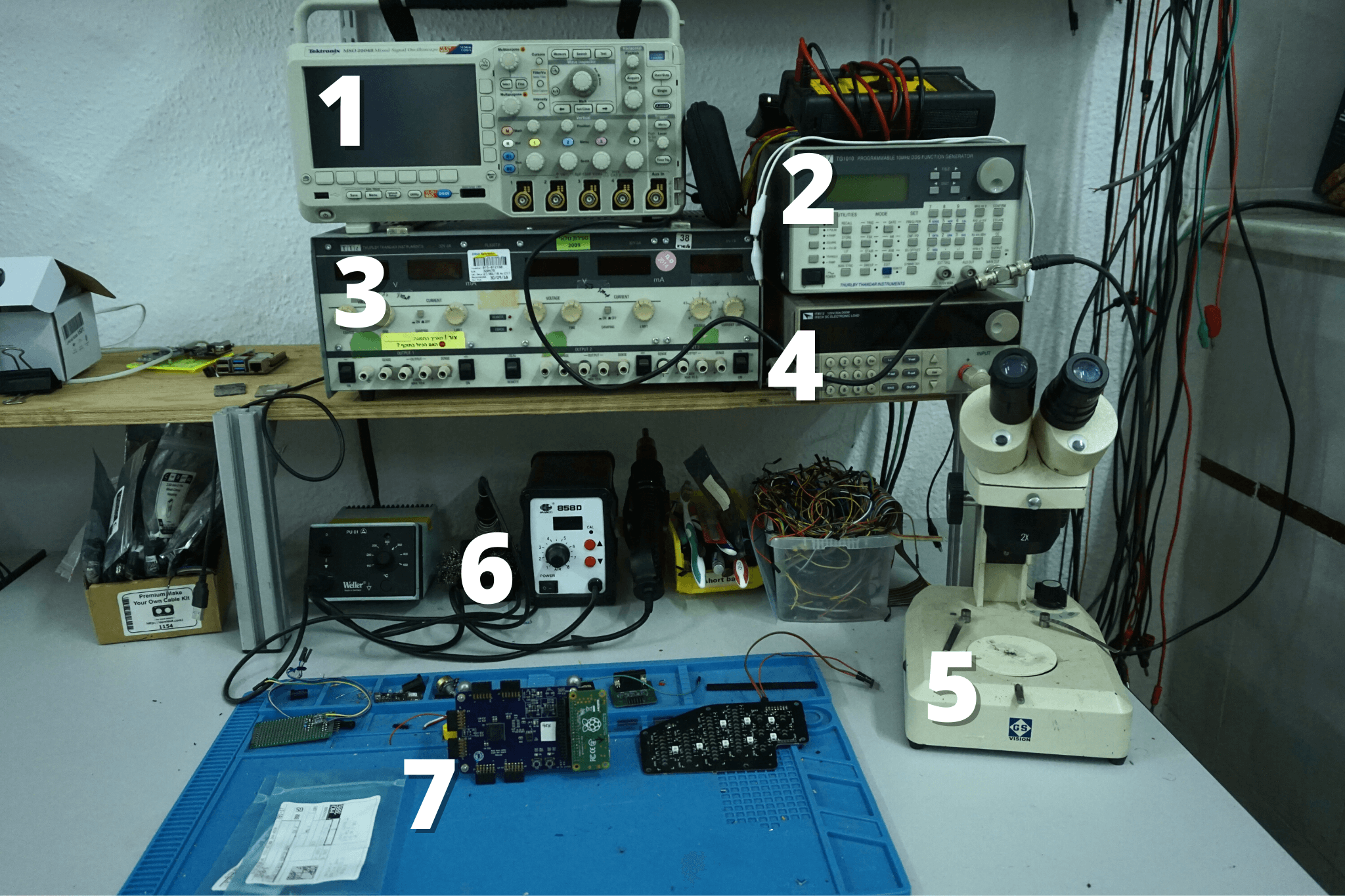

- Nice Tektronix scope, it has 4 analog channels and 20 digital. It’s a bit bandwidth limited to be honest though I rarely work above 100MHz. If I need a spectrum analyser then I often use an SDR.

- Signal generator - generates signals!

- 3 channel PSU, it can be controlled over serial which is nice for automating tests.

- Programmable Load. I used to develop power supplies, so having a load was very useful.

- Stereo microscope, without it I couldn’t do hand assembly of SMT parts.

- Soldering station and hot air for small designs and rework. I use paste, stencils and an oven if I’m doing a board with a bunch of components.

- A board I designed relatively recently, an open hardware FPGA dev board .

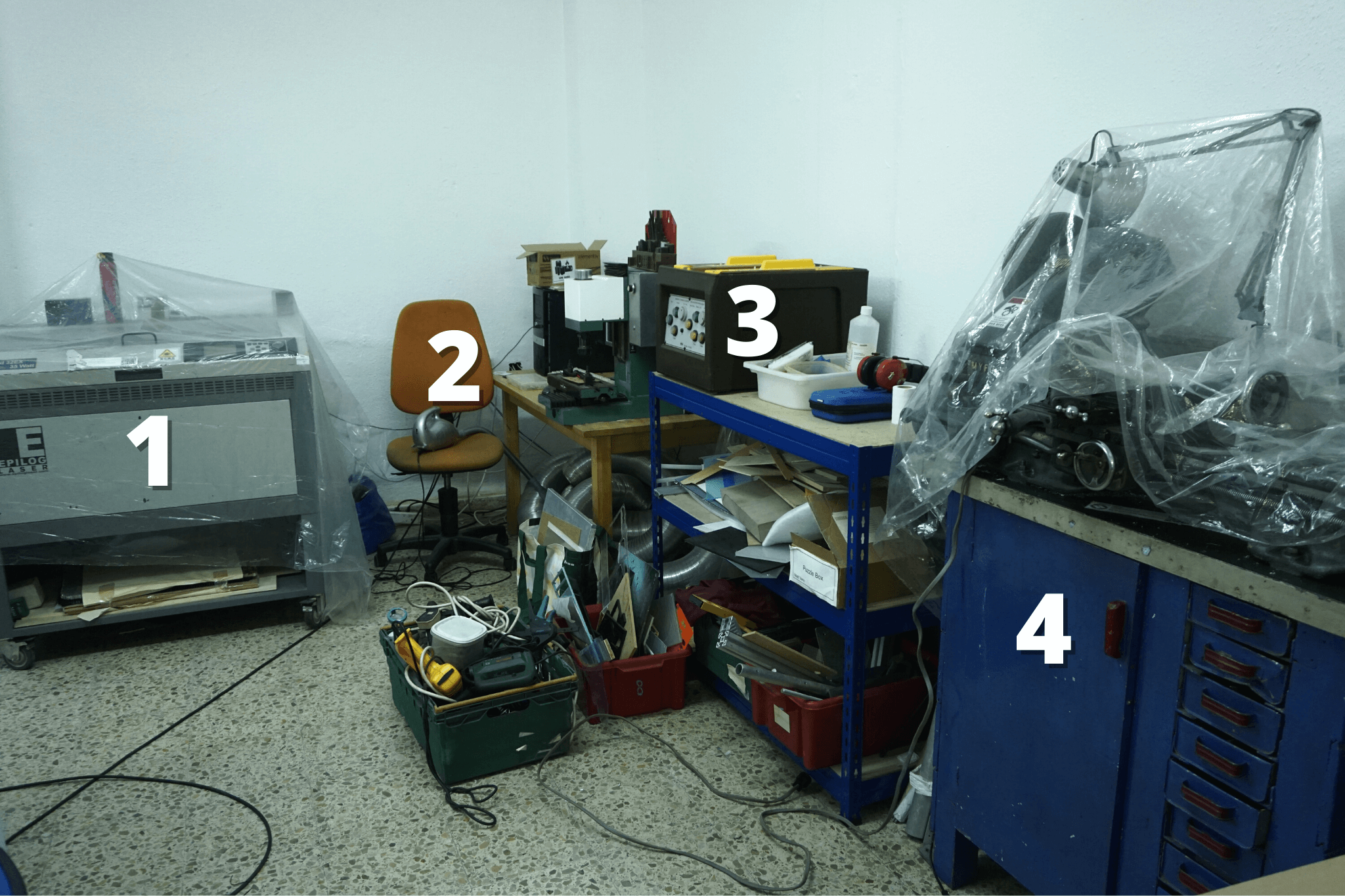

- Laser - very handy, but I don’t have proper extraction at the moment, which pretty much makes it unusable.

- CNC mill, I use LinuxCNC to control and Fusion360 for design and making tool paths. I try to avoid metal or anything that needs coolant. Delrin is lovely engineering plastic - pricey but easy to work with.

- PCB etching tank - very little use these days. I don’t do much urgent prototyping at the moment so I pretty much always use PCBWay for cheap and fast 2 and 4 layer boards.

- Lathe - occasional use, but when you need a lathe, it’s the best tool for the job! I brought this over to Spain from England - I find it quite funny having a 70 year old Myford lathe here!

No spam, ever. Unsubscribe without hurdle whenever you want